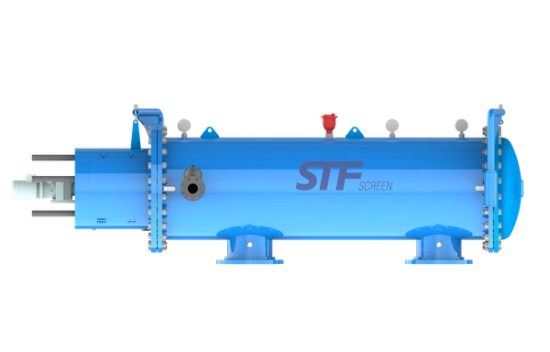

FMA 5000 / FMA 5000V

High-capacity self-cleaning electric screen filter for chemical, oil & gas, and industrial plants. Compact and efficient, it integrates multiple cartridges to maximize filtration surface and performance.

- automatic: Screen backwash cleaning system operates without manual input.

- electric: Three-phase drive with 24 V DC control for energy-efficient operation.

- horizontal and vertical: Available in horizontal (FMA-5000) and vertical (FMA-5000V) configurations to fit various industrial installation layouts.

The STF FMA-5000 and its vertical version FMA-5000V are self-cleaning electric screen filters designed for high-demand industrial applications, including chemical, petrochemical, and fluid treatment plants. They are engineered for high flows up to 5000 m³/h, using multiple cartridges to extend the filtration surface to 141,000 cm². The automatic backwash system operates in cycles up to 110 seconds, reducing water use and maintenance.

Constructed with high-resistance materials such as AISI-304/316 stainless steel and kiln-polymerized epoxy-polyester coatings, these filters are built for durability in harsh environments. Powered by up to 0.75 kW three-phase motors per unit and controlled via 24 V DC, the horizontal layout (FMA-5000) allows inline installation, while the vertical version (FMA-5000V) is ideal for compact setups. Filtration degrees range from 100 to 10 microns, meeting diverse process requirements.

- DS FMA 5000 - FMA 5000 V - TRI Ver.00.25.pdf

- FMA-5003V - TRILINGUAL GENERAL DRAWING.pdf

- FMA-5006V - TRILINGUAL GENERAL DRAWING.pdf

- FMA-5009V - TRILINGUAL GENERAL DRAWING.pdf

- FMA-5020 - TRILINGUAL GENERAL DRAWING.pdf

- Manual FMA 5000 - CPF01L-400-VE24 + power kit 4A · NO caja de empalmes - TRI 25.Ver.00.pdf

- Manual FMA 5000V - CPF01L-400-VE24 + power kit 2,5A · caja de empalmes - TRI 25.Ver.00.pdf

High-flow electric screen filter for demanding industrial environments

The FMA-5000 and vertical version FMA-5000V are engineered for precise filtration in high-volume industrial systems.

With a self-cleaning system and multiple cartridges, they maximize efficiency while minimizing maintenance.

They operate on three-phase motors and 24 VDC control, ensuring energy reliability and durability.

Perfect for chemical, oil & gas, and other industries needing compact, high-performance filtration.

Featured projects

Discover our projects

Albayet FIFA Stadium

Integrating a solution for the protection of the stadium's irrigation system and gardens.

+100 countries

Projects around the world

Stormwater system for the Brooklyn community, New York

Reducing water consumption in New York sanitation department facilities by reusing rainwater.

Farm Peculo Agropecuaria of Isábena

Construction and conditioning of several pig farms, collaborating with large sand filters.

We are always ready for new challenges

Contact

Experts in filtration solutions, hydraulic technology and fertigation.

Below you will find all the information you need to contact us. Find the right filtration solution for you

- info@stf-vican.com

- +34 974 40 15 48

- Polígono Armentera Parcela 86, 22400 Monzón, Huesca (Spain)